Brushless motor controllers, also known as electronic speed controllers (ESCs), are essential components in modern electric motor systems. They regulate the speed, direction, and torque of brushless DC motors, ensuring efficient and precise operation across various applications.

What is a Brushless Motor Controller?

A brushless motor controller is an electronic circuit that manages the performance of a brushless DC motor. Unlike traditional brushed motors, which rely on mechanical brushes for commutation, brushless motors use electronic controllers to switch the current in the motor windings. This creates a rotating magnetic field that the rotor follows. Electronic commutation results in higher efficiency, reduced maintenance, and a longer lifespan compared to brushed motors.

How Does a Brushless Motor Controller Work?

The primary function of a brushless motor controller is to convert direct current (DC) from the power source into alternating current (AC) to drive the motor. It achieves this through the following steps:

- Sensing Rotor Position

The controller determines the rotor’s position using sensors such as Hall effect sensors or by measuring back electromotive force (EMF) from the motor windings. - Switching Current

Based on the rotor’s position, the controller adjusts the timing and phase of current pulses to the stator windings. This creates a rotating magnetic field that propels the rotor. - Regulating Speed and Torque

By varying the frequency and amplitude of the current, the controller precisely controls the motor’s speed and torque to meet the desired performance parameters.

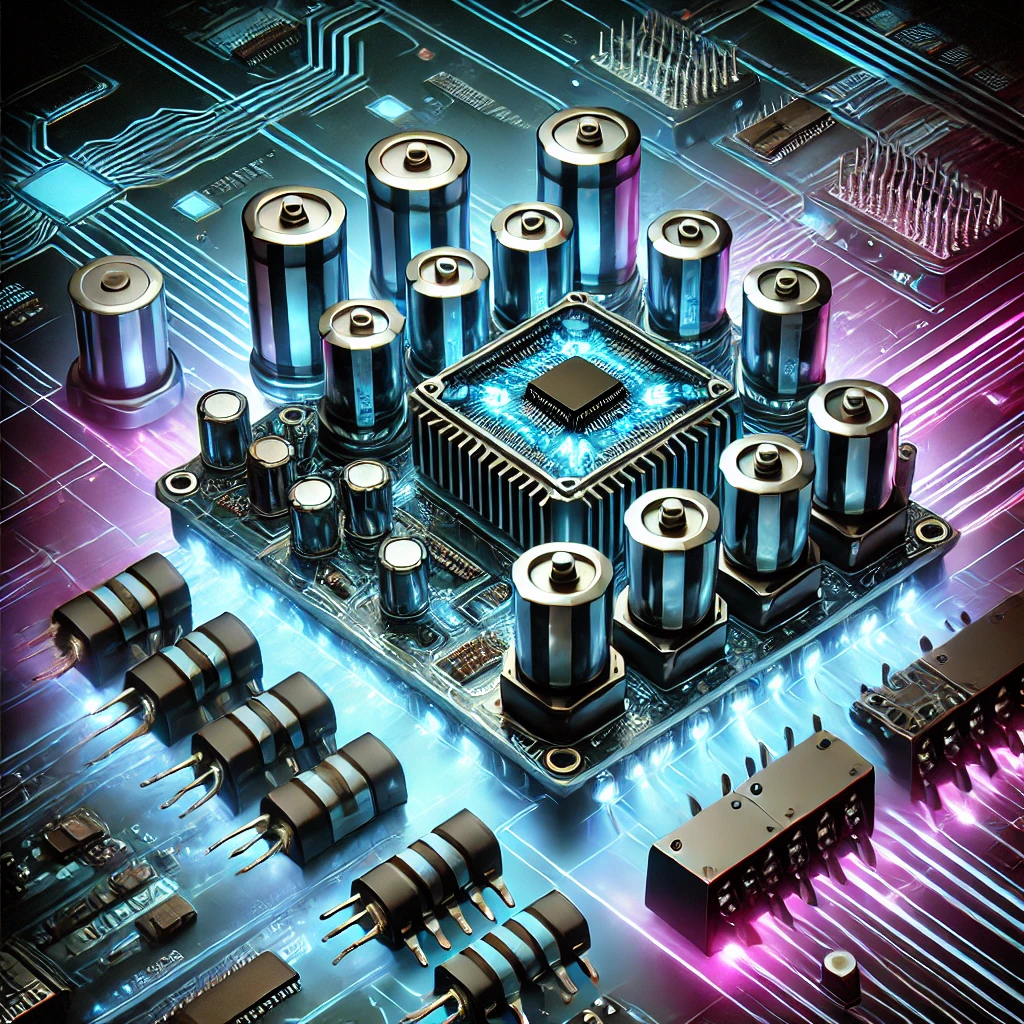

Key Components of a Brushless Motor Controller

A brushless motor controller consists of several critical components that work together to ensure smooth motor operation:

- Microcontroller Unit (MCU): Acts as the brain of the controller, processing input signals and executing control algorithms.

- Power Electronic Switches: Typically composed of field-effect transistors (FETs), these switches manage the flow of current to the motor windings.

- Gate Drivers: Interface between the MCU and power switches, ensuring proper operation of the FETs.

- Voltage Regulators: Maintain stable voltage levels for the controller’s internal components.

- Heat Sink and Cooling System: Prevents overheating and ensures long-term reliability.

Types of Brushless Motor Controllers

Brushless motor controllers can be categorised based on their control methodology and application requirements:

- Sensor-Based Controllers

These controllers use Hall effect sensors to detect rotor position, allowing precise commutation. They are preferred in applications requiring low-speed operation and high torque. - Sensorless Controllers

Sensorless controllers rely on back EMF detection for rotor position estimation. They are cost-effective, lightweight, and suitable for high-speed applications. - Field-Oriented Control (FOC) Controllers

FOC controllers use advanced algorithms to optimize motor performance by controlling magnetic field orientation. They provide smoother and more efficient operation and are commonly used in robotics and electric vehicles (EVs).

Advantages of Brushless Motor Controllers

Brushless motor controllers offer numerous benefits, including:

- High Efficiency: Electronic commutation reduces energy losses, resulting in higher efficiency compared to brushed motor systems.

- Low Maintenance: The absence of brushes eliminates wear and tear, reducing maintenance requirements.

- Enhanced Performance: Precise control over speed and torque allows for smoother operation and better responsiveness.

- Longer Lifespan: Reduced friction and heat generation extend the motor’s operational life.

Applications of Brushless Motor Controllers

Brushless motor controllers are widely used in various industries, including:

- Aerospace: Powering drones and unmanned aerial vehicles (UAVs) due to their lightweight and efficient design.

- Automotive: Used in electric vehicles (EVs) for propulsion and auxiliary systems.

- Industrial Automation: Driving motors in robotics, conveyors, and CNC machines for precise motion control.

- Consumer Electronics: Found in devices like computer fans, hard drives, and cordless power tools.

- Renewable Energy: Used in wind turbines and solar panel tracking systems for efficient energy conversion.

Selecting the Right Brushless Motor Controller

When choosing a brushless motor controller, consider the following factors:

| Factor | Description |

|---|---|

| Voltage & Current Ratings | Ensure the controller can handle the motor’s operating voltage and current requirements. |

| Control Features | Look for features like programmable settings, braking capabilities, and communication interfaces. |

| Thermal Management | Adequate cooling mechanisms are essential to prevent overheating during operation. |

| Type of Motor | Ensure compatibility with sensored or sensorless motors. |

| Application Needs | Choose a controller that suits your specific application requirements. |

Installation and Wiring Guidelines

To install a brushless motor controller correctly, follow these steps:

- Connect the Power Source

Ensure the voltage and current match the controller’s specifications. - Wire the Motor

Connect the three-phase motor wires (A, B, and C) to the corresponding controller terminals. - Attach the Sensors (If Applicable)

For sensored motors, connect the Hall sensor wires correctly to ensure proper commutation. - Configure the Controller

Use a programming interface to set up parameters like speed limits, braking, and acceleration. - Test the System

Run a low-speed test to check for proper operation before full-speed use.

Troubleshooting Common Issues

| Issue | Possible Cause | Solution |

|---|---|---|

| Motor not spinning | Incorrect wiring | Verify wiring connections. |

| Overheating | Poor ventilation or excessive load | Improve cooling and reduce load. |

| Erratic operation | Sensor misalignment or EMI interference | Recalibrate sensors and check for electromagnetic interference. |

Conclusion

Brushless motor controllers play a pivotal role in modern electric motor systems, offering efficient, reliable, and precise control. Understanding their functionality, types, and applications helps in selecting the right controller for various industries. Proper installation, configuration, and maintenance ensure optimal performance and longevity. Whether for drones, electric vehicles, or industrial automation, choosing the right brushless motor controller enhances efficiency and reliability.